View larger

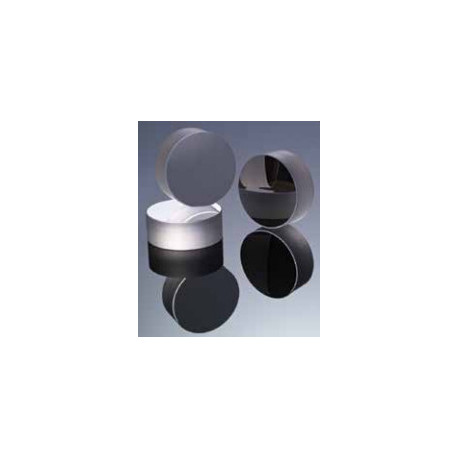

View larger Laser-Line Mirrors

Reference: ATF-MI1000-FY

The Laser-Line Mirrors of Advanced Thin Films provide superior film quality and uniformity results in environmentally stable optics with laser damage thresholds exceeding 40 J/cm2 at 1064 nm

- Download

- Send to a friend

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product description

This superior film quality and uniformity results in environmentally stable optics with laser damage thresholds exceeding 40 J/cm, wherein the high-energy laser mirrors more than 70 J/cm2 at 1064 nm and 20 ns.

Mirror coatings are available on flat or curved substrates and, because we use all-dielectric designs, they can handle the high laser powers of both CW and pulsed systems.

High-Energy Laser-Line Mirrors for 0° incidence

Model Number | MI 1000-FY | MI 1000-DY | MI 1000-TY | MI1000-QY |

Type | High-Energy Nd: YAG Mirrors | High-Energy Doubled Nd: YAG Mirrors | High-Energy Tripled Nd: YAG Mirrors | High-Energy Quadrupled Nd: YAG Mirrors |

Wavelength (nm) | 1064 | 532 | 355 | 266 |

Revlectivity | 99.9% at 0° | 99.9% at 0° | 99.9% at 0° | 99.9% at 0° |

Clear Aperture (%) | 85 | 85 | 85 | 85 |

Surface Figure | ?/10 | ?/10 | ?/10 | ?/10 |

Surface Quality | 10/5 | 10/5 | 10/5 | 10/5 |

Damage Threshold | 40J/cm2 @ 1064nm 20ns, 20Hz | 8J/cm2 @ 532nm 10ns, 20Hz | 3J/cm2 @ 355nm 10ns, 20Hz | 2J/cm2 @ 266nm 7ns, 20Hz |

Durability | MIL-PRF-13830B | MIL-PRF-13830B | MIL-PRF-13830B | MIL-PRF-13830B |

Diameter | 1 " +0/-0.010" | 1 " +0/-0.010" | 1 " +0/-0.010" | 1 " +0/-0.010" |

Thickness | 1/4" ±0.010" | 1/4" ±0.010" | 1/4" ±0.010" | 1/4" ±0.010" |

Substrate Material | Fused Silica | Fused Silica | Fused Silica | Fused Silica |

High-Energy Laser-Line Mirrors for 45° incidence

Model Number | MI 1045-FY | MI 1045-DY | MI 1045-TY | MI1045-QY |

Type | High-Energy Nd: YAG Mirrors | High-Energy Doubled Nd: YAG Mirrors | High-Energy Tripled Nd: YAG Mirrors | High-Energy Quadrupled Nd: YAG Mirrors |

Wavelength (nm) | 1064 | 532 | 355 | 266 |

Reflectivity | 99.9% at 45° | 99.9% at 45° | 99.9% at 45° | 99.9% at 45° |

Clear Aperture (%) | 85 | 85 | 85 | 85 |

Surface Figure | ?/10 | ?/10 | ?/10 | ?/10 |

Surface Quality | 10/5 | 10/5 | 10/5 | 10/5 |

Damage Threshold | 40J/cm2 @ 1064nm 20ns, 20Hz | 8J/cm2 @ 532nm 10ns, 20Hz | 3J/cm2 @ 355nm 10ns, 20Hz | 2J/cm2 @ 266nm 7ns, 20Hz |

Durability | MIL-PRF-13830B | MIL-PRF-13830B | MIL-PRF-13830B | MIL-PRF-13830B |

Diameter | 1 " +0/-0.010" | 1 " +0/-0.010" | 1 " +0/-0.010" | 1 " +0/-0.010" |

Thickness | 1/4" ±0.010" | 1/4" ±0.010" | 1/4" ±0.010" | 1/4" ±0.010" |

Substrate Material | Fused Silica | Fused Silica | Fused Silica | Fused Silica |

Why Dielectric instead of Metal?

Downloads - Laser-Line Mirrors

Catalogue Advanced Thin Films Premium Laser Optics and Coatings

Download (1.24M)

Laser-Line Mirrors

Laser-Line Mirrors