Tuning Fork Resonant Choppers

Reference: EOP-CH-zz

- Send to a friend

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product description

The tuning fork chopper is a FIXED FREQUENCY electromechanically driven light chopper.

Vanes attached to moving tines of a fork modulate a light beam. The chopper operates at the natural resonant frequency established by the effective mass of the moving assembly and the spring constant of the tines.

Chopping frequency ranges from 10 Hz to 6 KHz, apertures up to 15mm are practical in the lower frequencies (under 100 Hz), 0.5mm at 3 KHz and 0.2mm at 6 KHz. If the beam size is limiting the chopper rate, consider focusing at the chopper to reduce the beam size. The amplitude of the motion of the chopper is inversely proportional to its frequency. You will find examples of the frequency amplitude relationship in the table below. Dark or bright vanes are standard; mirrors, lenses or gratings optional.

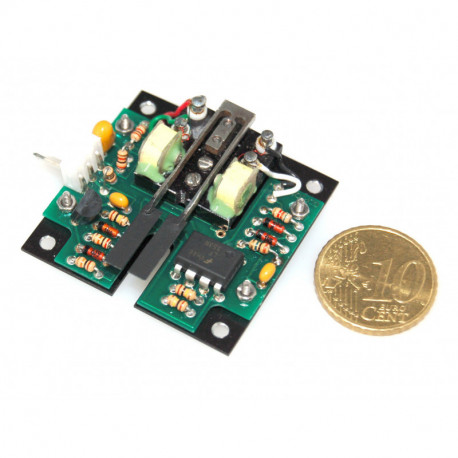

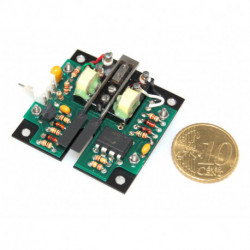

Low cost, compact size, lightweight and virtually unlimited life make the tuning fork choppers especially suitable for dedicated applications, OEM, built into an instrument or system, and for portable systems.

Balanced operation and high "Q" insure excellent frequency stability, low electrical drive power and low reaction forces. High flexural stiffness provides good resistance to shock and vibration. Tuning fork choppers are cryogenic and high temperature (200°C) capable. They can be constructed of low out-gassing materials for ultra high vacuum (10

The ED driver and the AGC driver are both tuning fork oscillators using the chopper as a frequency source. The AGC driver also provides a high amplitude stability (0.005%) and both sine wave and TTL reference signals.

The PLD-1C driver will phase lock the chopper to an external clock signal.

The PLD-2C driver will phase lock two choppers in a "master/slave" chopping system.

Special vane configurations, modulating waveforms and shapes are available as a special order (consult EOPC). Drive electronics with different package, regulation and power supply options are available. Special pricing is also available for OEM applications.

CH-10 Optical Modulator:

ONE FIXED FREQUENCY from the range of 10Hz to 1kHz

For 50% duty cycle, the opening at rest is zero.

The standard base holds a single coil.

A base with two coils is recommended for low frequency

and high amplitude stability (with the AGC driver) and

for a wide temperature range.

A base with three coils is recommended for high

frequencies and high amplitude stability (with the AGC

driver) and for a wide temperature range.

The vane motion is sinusoidal

Standard operating temp.:-40°C to +65°C

CH-20 Optical Modulator:

ONE FIXED FREQUENCY from the range of 200Hz to 6kHz

For 50% duty cycle, the opening at rest is zero.

The vane motion is sinusoidal

Standard operating temp.:-40°C to +65°C

The following should serve as guide lines only

Vanes attached to moving tines of a fork modulate a light beam. The chopper operates at the natural resonant frequency established by the effective mass of the moving assembly and the spring constant of the tines.

Chopping frequency ranges from 10 Hz to 6 KHz, apertures up to 15mm are practical in the lower frequencies (under 100 Hz), 0.5mm at 3 KHz and 0.2mm at 6 KHz. If the beam size is limiting the chopper rate, consider focusing at the chopper to reduce the beam size. The amplitude of the motion of the chopper is inversely proportional to its frequency. You will find examples of the frequency amplitude relationship in the table below. Dark or bright vanes are standard; mirrors, lenses or gratings optional.

Low cost, compact size, lightweight and virtually unlimited life make the tuning fork choppers especially suitable for dedicated applications, OEM, built into an instrument or system, and for portable systems.

Balanced operation and high "Q" insure excellent frequency stability, low electrical drive power and low reaction forces. High flexural stiffness provides good resistance to shock and vibration. Tuning fork choppers are cryogenic and high temperature (200°C) capable. They can be constructed of low out-gassing materials for ultra high vacuum (10

The ED driver and the AGC driver are both tuning fork oscillators using the chopper as a frequency source. The AGC driver also provides a high amplitude stability (0.005%) and both sine wave and TTL reference signals.

The PLD-1C driver will phase lock the chopper to an external clock signal.

The PLD-2C driver will phase lock two choppers in a "master/slave" chopping system.

Special vane configurations, modulating waveforms and shapes are available as a special order (consult EOPC). Drive electronics with different package, regulation and power supply options are available. Special pricing is also available for OEM applications.

CH-10 Optical Modulator:

ONE FIXED FREQUENCY from the range of 10Hz to 1kHz

For 50% duty cycle, the opening at rest is zero.

The standard base holds a single coil.

A base with two coils is recommended for low frequency

and high amplitude stability (with the AGC driver) and

for a wide temperature range.

A base with three coils is recommended for high

frequencies and high amplitude stability (with the AGC

driver) and for a wide temperature range.

The vane motion is sinusoidal

Standard operating temp.:-40°C to +65°C

CH-20 Optical Modulator:

ONE FIXED FREQUENCY from the range of 200Hz to 6kHz

For 50% duty cycle, the opening at rest is zero.

The vane motion is sinusoidal

Standard operating temp.:-40°C to +65°C

The following should serve as guide lines only

Tuning Fork Resonant Choppers

Tuning Fork Resonant Choppers