Optical Tester

Reference: PHV-WaveGauge

- Send to a friend

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product description

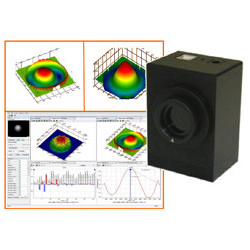

WaveGauge® are turnkey solutions based on Digital Wavefront Technology designed to meet the most demanding requirements for quality assurance, research & development and production environments.

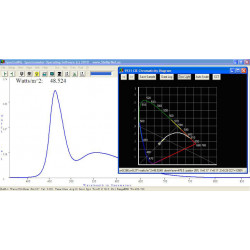

WaveGauge® provides real time analysis of lenses with high speed, accuracy and unprecedented resolution. Simultaneous intensity and high-resolution wavefront mapping enables surface quality visualization and aberration analysis of most complicated lenses with spherical, aspheric or toric shape.

All critical parameters in lens testing such as MTF, PSF, aberrations, surface quality, can be accurately measured and compared with lens design or reference data.

A broad range of applications

Designed for Ultimate Performance

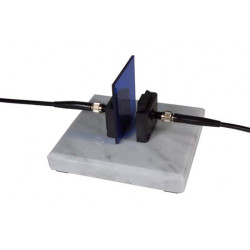

WaveGauge® system has been designed in transmission setup to optimize aberrations and MTF measurements. Standard configuration contains specially designed collimated light source, a lens holder and PhaseView's Digital Wavefront Camera®. All parts are fully enclosed in an ergonomic packaging to avoid parasitic light and contamination coming from dust and particles.

The software includes a supervisor level adapted to R&D tasks with various ways of displaying results and extended analysis features and an operator level for routine and production purpose with pass / fail analysis to increase productivity and throughput.

Conventional methods have various limitations for measuring aspherics and ophthalmic lenses, those limitations include either resolution and dynamic range, measurement speed, sensitivity to vibrations or non measured parameter such as modulation transfer function.

Interferometers and Shack-Hartmann based wavefront sensors are the leading technologies for lens testing. Nowadays, wavefront sensing is considered in this market as cutting-edge technology with numerous advantages: flexibility, reliability, vibration free and as cost effective metrology tool.

WaveGauge® systems are based on Digital Wavefront Cameras® that represent state-of-the art wavefront sensing technology as new generation of wavefront sensors offering strong value added versus conventional Shack-Hartmann sensors.

High Dynamic Range compared to Interferometers

Shack-Hartmann wavefront sensors and Digital Wavefront Cameras® are both able to measure wavefronts with strong aberrations which are not accessible with interferometers. The lack of dynamic range in interferometers is solved at the expense of diffractive null optics that need to be designed for each type of measured lens which is less flexible and much more expensive.

High Resolution compared to Shack-Hartmann sensors

Digital Wavefront Cameras® provide high resolution native wavefront maps as their spatial resolution is directly related to CCD resolution. Instead of using lenslet array for detecting wavefront distortion, Digital Wavefront Cameras® use intensity signal to extract phase information thereby overcoming the inherent limitation of Shack-Hartman sensors: number of lenslets (spatial resolution) over dynamic range.

The additional advantage is that the intensity image in Digital Wavefront Cameras® is similar to CCD camera's image, and not only a series of dots that are not meaningful in terms of information about lens properties. In other words, with Digital Wavefront Cameras®, "what you see is what you measure".

Combining high dynamic range and high spatial resolution, WaveGauge® can produce highly repeatable measurements of both low-order and high-order aberrations for any complex lens design and meets the most demanding requirements of high-end R&D laboratories and production facilities.

Measured Parameters

These parameters can be measured both in air and in situ, due to the capability of the software for changing the refractive index of substrate material and as well as of the medium. WaveGauge® has the capability of measuring lens dioptric power at different diameters, especially for multifocal IOL's. MTF is measured at different diameters of the IOL.

Wavefront Sensor Parameters

Lens Measurement Capabilities

WaveGauge® provides real time analysis of lenses with high speed, accuracy and unprecedented resolution. Simultaneous intensity and high-resolution wavefront mapping enables surface quality visualization and aberration analysis of most complicated lenses with spherical, aspheric or toric shape.

All critical parameters in lens testing such as MTF, PSF, aberrations, surface quality, can be accurately measured and compared with lens design or reference data.

A broad range of applications

- Microlenses in mobile phones

- digital cameras

- pickup lenses for optical storage drives

- single aspherics used to build compact imaging systems

- Ophthalmic lenses such as contact lenses, monofocal

spherical, cylinder, toric, as well as multifocal Intraocular

lenses (IOL)

Designed for Ultimate Performance

WaveGauge® system has been designed in transmission setup to optimize aberrations and MTF measurements. Standard configuration contains specially designed collimated light source, a lens holder and PhaseView's Digital Wavefront Camera®. All parts are fully enclosed in an ergonomic packaging to avoid parasitic light and contamination coming from dust and particles.

The software includes a supervisor level adapted to R&D tasks with various ways of displaying results and extended analysis features and an operator level for routine and production purpose with pass / fail analysis to increase productivity and throughput.

Conventional methods have various limitations for measuring aspherics and ophthalmic lenses, those limitations include either resolution and dynamic range, measurement speed, sensitivity to vibrations or non measured parameter such as modulation transfer function.

Interferometers and Shack-Hartmann based wavefront sensors are the leading technologies for lens testing. Nowadays, wavefront sensing is considered in this market as cutting-edge technology with numerous advantages: flexibility, reliability, vibration free and as cost effective metrology tool.

WaveGauge® systems are based on Digital Wavefront Cameras® that represent state-of-the art wavefront sensing technology as new generation of wavefront sensors offering strong value added versus conventional Shack-Hartmann sensors.

High Dynamic Range compared to Interferometers

Shack-Hartmann wavefront sensors and Digital Wavefront Cameras® are both able to measure wavefronts with strong aberrations which are not accessible with interferometers. The lack of dynamic range in interferometers is solved at the expense of diffractive null optics that need to be designed for each type of measured lens which is less flexible and much more expensive.

High Resolution compared to Shack-Hartmann sensors

Digital Wavefront Cameras® provide high resolution native wavefront maps as their spatial resolution is directly related to CCD resolution. Instead of using lenslet array for detecting wavefront distortion, Digital Wavefront Cameras® use intensity signal to extract phase information thereby overcoming the inherent limitation of Shack-Hartman sensors: number of lenslets (spatial resolution) over dynamic range.

The additional advantage is that the intensity image in Digital Wavefront Cameras® is similar to CCD camera's image, and not only a series of dots that are not meaningful in terms of information about lens properties. In other words, with Digital Wavefront Cameras®, "what you see is what you measure".

Combining high dynamic range and high spatial resolution, WaveGauge® can produce highly repeatable measurements of both low-order and high-order aberrations for any complex lens design and meets the most demanding requirements of high-end R&D laboratories and production facilities.

Measured Parameters

- Diopter power and power maps

- Lens aberrations to an arbitrary order

- Point Spread Function (PSF)

- Modulation Transfer Function (MTF)

- Effective Focal Length (EFL)

These parameters can be measured both in air and in situ, due to the capability of the software for changing the refractive index of substrate material and as well as of the medium. WaveGauge® has the capability of measuring lens dioptric power at different diameters, especially for multifocal IOL's. MTF is measured at different diameters of the IOL.

Wavefront Sensor Parameters

- Sensor: CCD

- Resolution: 1392x1040

- Frame Rate: 15 Hz

- Optical Format: 2/3"

- Pixel Dimensions: 6,45 µm x 6,45 µm

- Pixel Bit Depth: 12

- Camera Dynamic Range: 66 dB

- Wavelength Range: 350-1100 nm

- Wavefront Measurement Points: 500x500

Lens Measurement Capabilities

- Aperture diameter: 0,5-6 mm (20 mm with adaptor)

- Power Range: -20 to + 20 D

- Power absolute accuracy: 0,1 to 0,3%

- Power resolution: 0,01 D

- Power map lateral resolution: 6,45 µm

- MTF absolute accuracy: 2% MTF

- Wavefront measurement absolute (relative) accuracy rms: <lamda/20 (lamda/50)

- Light source Wavelength: 535 nm +/- 15 nm

- Measurement time for 1 lens including Power, MTF and aberrations: 1 sec

Mechanical & Electrical Specs- Computer Interface: USB 2.0

- Power: 110 / 220 VAC

- Dimensions: 67,5 cm x 18,5 cm x 15,5 cm

- Weight: 6 Kg

Hard- and Software requirements:- Pentium 4; min. 1 GHz, min. 1 GB

- OS: XP, Vista, Windows 7

- USB 2.0 (500 mA Interface)

- NVIDIA GPU with 512 MB

Optical Tester

Optical Tester